Maddocks Group

Industrial Filter Division

1-800-263-8660

(905) 549-9626

sales@maddocksgroup.com

663 Woodward Avenue

Hamilton, Ontario, Canada L8H 6P3

BEANE™ EFFICIENCY RATINGS

Click here to download Beane™ Efficiency Ratings

Unlike conventional woven and needlefelt textiles, seamless tube Beane™ Bags and Beane™ wide width materials are knit fabrics consisting of a patented “loop pile” surface. The thickness and fiber density of the knit fabric provides a high permeability, reducing pressure drop conditions, with excellent filtration efficiencies of 99.5 to 99.99%. The physical movement of the loop pile surface on the cleaning cycle easily removes heavy dust formations while preventing blinding or plugging of the fabric. When eliminating the seams with our circular knitted material it offers additional filter area providing increased airflow.

The Beane™ fabric is also offered in the Static Eliminator (SE) version. Beane™ SE fabrics are made with electrically conductive carbonized yarns. Where dusts sensitive to ignition are being filtered, the addition of these yarns can improve bag house safety by constantly drawing off static-charges to ground. SE fabrics will also combat “Static Cling” or serious cases of dust hang up due to opposing static charges between the dust and the filter bag.

The Beane™ material is a washable fabric in cold water and hung to dry. It can withstand washings for a number of years without any breakdown in the products performance or efficiency.

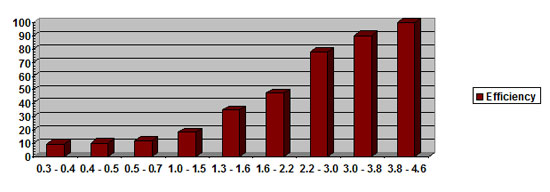

PARTICAL SIZE - vs - INITIAL REMOVAL EFFICIENCY

X - axis is the efficiency rating in percentage

Y - axis is the micron size as per efficiency

Beane™ T-150 Media

As the chart shows the efficiency rating for a 4.6 micron is 99.99 %

The efficiencies start to increase at the 2.2 to 3.0 micron stage at 78.15%